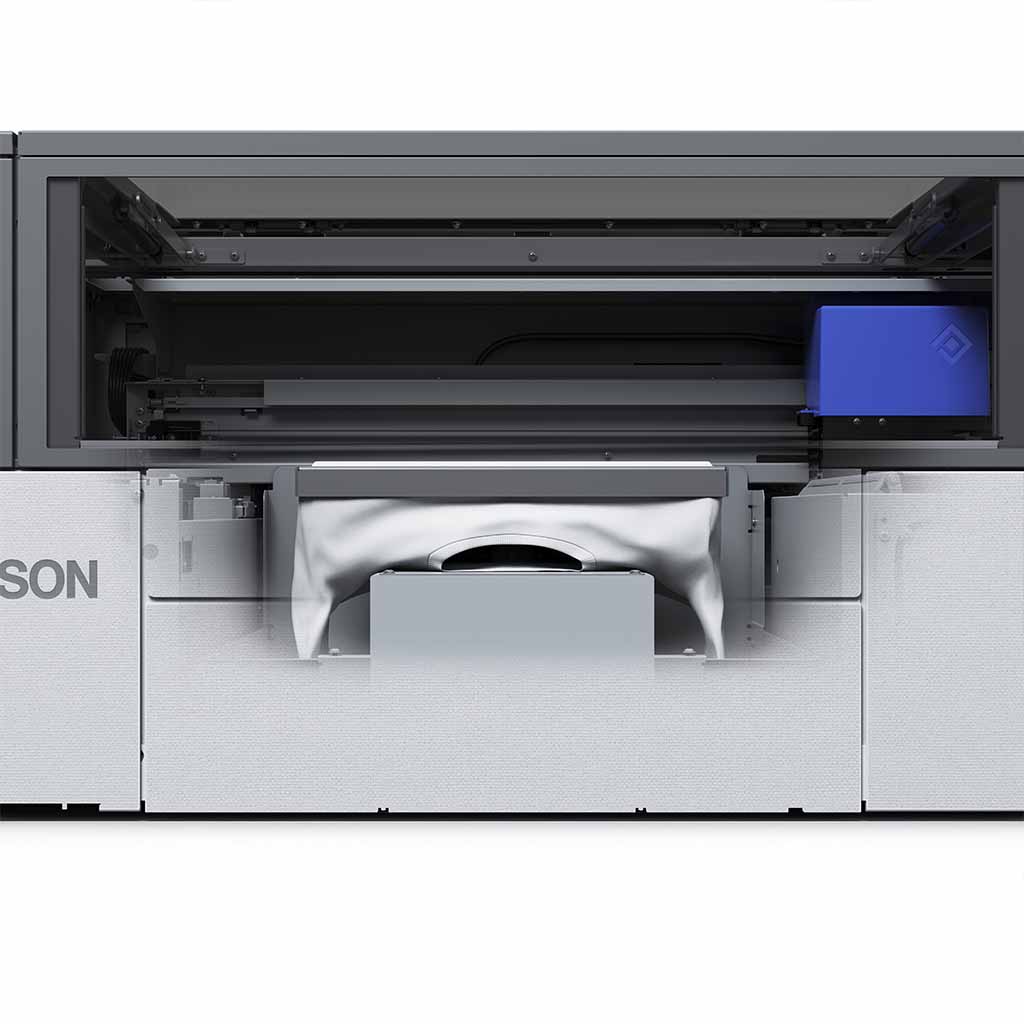

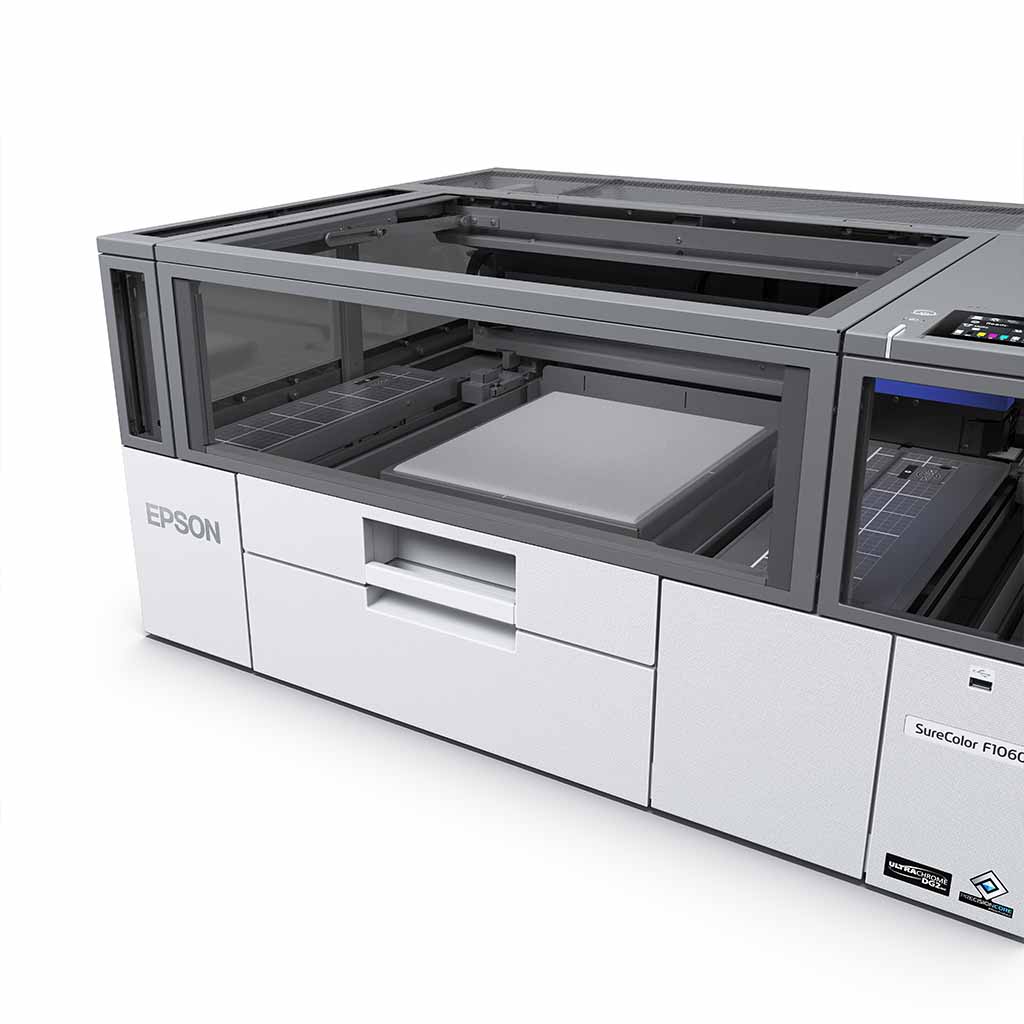

The SureColor F1060 is designed for in-store clothing and merchandise customisation. It also provides a cost-effective production tool for designers, event operators, print-for-pay providers and small businesses. The printer combines a compact footprint with flexible operation and outstanding image quality. It supports traditional direct-to-garment (DTG) and the latest direct-to-film (DTFilm) production techniques. The unit ships complete with software and an integrated PORT service for enhanced management and support. It is simple to operate, and features fully automated height adjustment and a high degree of self-maintenance. Pouch-based ink and a maintenance tank make for high-convenience with minimum fuss and mess.

The SC-F1060 is not only compact but has been styled to suit ‘front-office’ operations with a quality finish and fully enclosed production area. It uses Epson’s latest UltraChrome® DG2 ink, and incorporates our famous PrecisionCore® MicroTFP® printhead and operates with Precision Dot imaging technology. Super-fine lines, exceptional gradations and solid fills can be produced on a wide range of fabric and film. Ink ships in convenient ink pouches that are compact to store, quick to load and easy to replace.

The SC-F1060 is designed for low-volume business, event and design applications. It combines small size with high-flexibility and maximum image quality. It uses Epson’s latest UltraChrome DG2 ink, PrecisionCore thin film printhead and Precision Dot image processing. Auto print height setting, auto head cleaning and active nozzle management ensure consistent high-quality output. It can be operated on a moderate-sized desk with minimal installation space and operational clearance.

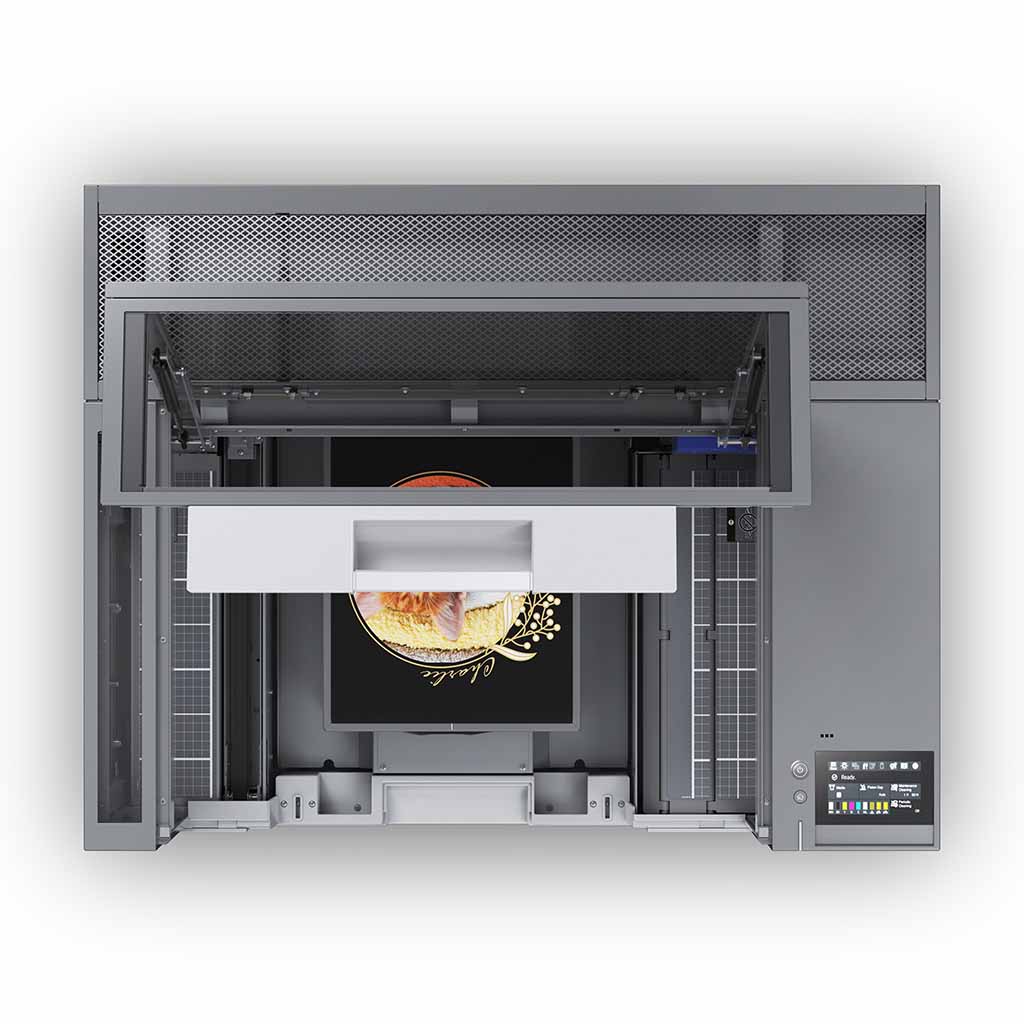

Epson UltraChrome DG2 ink supports both DTG and DTFilm production techniques. When used with appropriate pre-treat solution, film and powder, custom images can be applied to a wide range of materials. Images feature enhanced UV/wash durability with superior resolution and colour. Epson consumables feature reduced toxicity over competitors, making them safer to work with. When applied to fabric and appropriately fixed, they adhere to the latest Oeko-Tex® Eco Passport and GOTS-ECOCERT standards, ensuring that the garments are safe for use by adults, children and babies.3, 4

Direct-to-garment printing replaces the complex, messy and time-consuming process of traditional screen printing with a faster, more flexible, and repeatable digital solution. Artwork can be created using a range of readily available drawing and photo editing programs before printing directly onto fabric, or film for subsequent transfer onto other material via a heat press. The process provides increased scope for creativity, value-adding and customisation while enabling significant cost savings and just-in-time/ just-the-right-volume production.

The SureColor F1060 combines an ergonomic design with quality presentation and simple operation. It features compact, fully enclosed work area with a see-through top and lit interior. Garment placement is facilitated by a pull-out guide for the neck, along with integrated sleeve alignment guides. These guides are synchronised with the supplied software, providing an on-screen preview for precise alignment. Print height adjustment is fully automated while 5-colour CYMK + White ink operation enables output on film, light and dark fabric.3

As with all models in the current Epson DTG range, the SC-F1060 supports premium frame-based output as well as rapid frame-less output with user-replaceable grip pads. The control panel features integrated help and there are online videos that provide further assistance. The printer comes with the latest Epson Garment Creator software and connects with Epson Cloud Solution PORT for advanced management, reporting, production costing and support.5, 6

The SureColor F1060 features a high degree of self-maintenance. The printhead is self-cleaning and operates with a self-washing capping system for enhanced reliability and reduced user-maintenance. Optional platens are available for sleeve work and to enable production of baby clothing.

The SC-F1060 was designed for easy management. It uses 250 ml pouches that load via a simple tray system and a convenient maintenance tank. The printhead provides durable operation without the cost and labour associated with regular replacement. The head is covered under warranty and CoverPlus, extendable up to 5 years. The integrated (free) Epson Cloud Solution PORT service not only provides operators with advanced costing and reporting tools, but also enhanced service and support with Epson technicians able to undertake remote diagnosis for expedited resolution5.

Epson F1060 Specifications:

Epson F1050 Size:

| Max Print Area | 254 x 305 mm (using small platen) | |

| Form Factor | Compact desktop | |

Epson F1060 Print Technology:

| Printhead | PrecisionCore® MicroTFPTM | |

| Print Modes | Uni and bi-directional | |

| Configuration | 400 nozzles x 6 lines | |

| Max Resolution | 2400 x 1200 dpi | |

| Minimum Ink Droplet Size | 12.8 pl | |

| Features | Fan-less operation Auto head wiping Fully enclosed workspace Full auto height adjustment Self-washing capping system Ink-less nozzle status monitoring Auto nozzle replacement/recovery Variable Sized Droplet Technology | |

Epson F1060 Ink System:

| Ink Family | Epson Ultrachrome® DG2 | |

| Ink Technology | Direct-to-garment (DTG)/ Direct-to-film (DTFilm) | |

| Ink Formulation | All-pigment | |

| Loading | Pouch-based | |

| Capacity | 5 x 250 ml ink 1 x 250 ml maintenance liquid | |

| Configuration Options | CYMKW + Ml with auto white ink recirculation | |

Epson F1060 Performance:

| DTG Dark Shirt (White + Colour) | Fast: 200s Production: 240s | |

| DTG Light Shirt (Colour Only) | Fast: 55s Production: 100s | |

| Film (White + Colour) | Fast: 200s Production: 285s | |

| DTG & Film (White Only) | Fast: 105s Production: 240s | |

| Figures are print speed for an A4 print of the image shown output using Epson Garment Creator 2. The printer supports a range of modes to suit different workflow, application, and quality requirements. Customers are recommended to check with their dealer to determine the most appropriate mode and the speed that can be achieved. It should be noted that actual print times will vary depending on a range of variables including the printer configuration, image size and type, print mode, software selection, PC specification, and networking configuration. It should also be noted that for direct-to-garment operation additional time will be required for pre-treatment, loading, flattening, unloading and fixing while direct-to-film operation will require time for powder application, liquefaction and transfer. | |

Epson F1060 Media Support:

| Direct-To-Garment | Untreated moderate to loose weave fabric Optimal results with material containing 50% or more cotton Can also be used with selected polyester material (requires polyester pre-treat with customers recommended to test fabric before commencing production) | |

| Direct-To-Film | Can be used with a range of third-party film and powder types Results vary by brand (test before commencing production) | |

| Max Thickness & Weight | 25 mm, 1.5 kg per item | |

| Max Print Area | Small platen: 254 x 305 mm (included) Extra small platen: 178 x 203 mm Sleeve platen: 102 x 102 mm | |

Epson F1060 Operation:

| Control Panel | 4.3″ colour LCD with touch control | |

| Interface | Ethernet 1000Base-T or Wi-Fi IEEE802.11n/ac connection is recommended Also supports 10/100Base-T Ethernet, IEEE802.11b/n/a Wi-Fi, Hi-Speed USB 2.0 & SuperSpeed USB 3.0 Front panel USB enables direct file upload and storage (<2 TB, FAT32 format, files may need to be pre-processed) | |

| Memory | 1 GB | |

| Software | Web download: Communications Driver, Web Installer*, Manual Package*, Software Updater*, Firmware Updater*, EpsonNet Setup, EpsonNet Config & EpsonNet Print. Epson Garment Creator 2* and Photoshop Plugin, Epson Edge Dashboard (DTG Edition)* Online: Epson Cloud Solution PORT for job costing, production management & enhanced support* | |

| *Windows & Mac compatible. All other applications are Windows only except for PORT which can be accessed via a standard web browser or dedicated Android/Mac app (free download from the relevant app stores). | ||

Epson F1060 Environmental:

| Operational Temperature | 10 – 35° C (15 – 35° C recommended) | |

| Operational Humidity | 20% – 80% with no condensation | |

| Power Supply | 110 – 240 V, 50 Hz – 60 Hz AC, 1.4 A | |

| Recommended Install Space | 900 x 1200 x 940 mm | |

| Recommended Installation | A table 600 – 800 mm high that will hold at least 85 kg and enable operation without vibration | |

| Power Consumption | 40 W operating, 20 W ready, 6 W sleep | |

| Operating Noise | 34 dB | |

Epson F1060 Physical:

| Dimensions & Weight | 899 x 699 x 426 mm, 71 kg (small platen, no ink) | |

| Packaging | 1200 x 871 x 730 mm, 100 kg (main unit) | |

Epson F1060 Package Contents:

| Printer, power cord, maintenance tank, 1 x maintenance liquid pouch, 1 set of ink + additional white, 5 litres cotton pre-treat, 1 x small platen, 1 x grip pad, 1 x garment flattening tool, 1 x head cleaning kit, 1 x maintenance kit, 1 x ink initialisation/charging unit, set-up guide. All software is delivered via Web download. Internet connection will also be required for PORT activation and on-going printer connection. | ||

| NOTE: A significant proportion of the supplied ink will be consumed during initialisation with customers recommended to consider purchase of an additional set. The printer must be initialised for 5-colour operation. If white ink is not required, it can subsequently be replaced with cleaning fluid (available separately). |

Epson F1060 System Requirements:

A PC will be required for installation and operation of this printing system. When using the USB Direct Print function files must be processed through Garment Creator first.

Garment Creator 2 requires a PC or Mac with a processor that has power equivalent or better than an Intel Core i7 8th generation, at least 2 GB memory (16 GB recommended), 32 GB or more storage (SSD recommended), Win 8.1 64-bit / Mac OS 10.12 or higher and a monitor with at least 1024 x 768 resolution.

A third-party heat press with adjustable temperature, pressure and timer will generally be required. Presses can be sourced from a number of suppliers in various sizes and formats. Contact your dealer for details.

DTG operation generally requires fabric to be pre-treated. Some garment suppliers provide stock pre-treated. If using untreated stock, it will need to be processed; this can be done manually (roller or spray application) however a pre-treatment machine is recommended for optimum results.

Direct-to-film (DTFilm) operation will require additional 3rd party film and powder. For optimum results an oven is also recommended. Powder application must be done away from the printer. Different films and powders behave differently with customers recommended to consult with their dealer for advice on brand selection, print and process settings.

- Compact design – clean styling with flat sides, rear and top. Has a relatively low weight and a footprint of just 0.62 m1

- Flexible production – 5c CYMKW ink set for imaging on light and dark on a range of material via DTG or DTFilm2

- Easy to install – fits through a standard door, designed for Ethernet or Wi-Fi connection, ships with ink and software.

- Easy to operate – uses front-loaded 250 ml ink pouches and a simple maintenance tank, easy garment placement with fully automatic height adjustment.

- Enhanced reliability – comprehensive onsite warranty with optional CoverPlus for up to five years total cover (including the printhead) linked with Epson Cloud Solution PORT.

- Outstanding print quality – latest ink, printhead and image processing technology produce output of super-fine lines, solid fills and excellent gradations in bright colour with minimum bleed on a wide range of fabrics.

- Easy to manage and maintain – ink-less nozzle status monitoring, auto-nozzle replacement and auto head cleaning ensure consistent results with reliable operation and minimum user maintenance. Integrated (free) PORT service provides advanced costing, management and reporting tools while also facilitating remote diagnosis and enhanced support.1

- If hardware repair is required, Epson will generally perform this free onsite within greater metro locations (regional locations attract additional travelling charges). Cover can be extended up to a maximum total of 5 years through the purchase of optional CoverPlus. CoverPlus requires activation of an Epson Cloud Solution PORT account and connection of the printer. For further information, please see the specification tab.

- A range of material and fabric types are supported by DTG and DTFilm processes. Selecting the optimal process will depend on the material, image type and preferred workflow. It is important to discuss your requirements with Epson and/or your dealer prior to purchase. Most production methods require purchase of additional equipment which should also be discussed with your dealer prior to purchase. The printer is designed to operate in a 5-colour configuration. If white ink is not required for a period of time, it can be replaced with the cleaning liquid (available separately).

- A range of material and fabric types are supported by DTG and DTFilm processes. Selecting the optimal process will depend on the material, image type and preferred workflow. It is important to discuss your requirements with Epson and/or your dealer prior to purchase. Most production methods require purchase of additional equipment which should also be discussed with your dealer prior to purchase. The printer is designed to operate in a 5-colour configuration. If white ink is not required for a period of time, it can be replaced with the cleaning liquid (available separately).

- When applied to fabric and appropriately fixed Epson DS2 ink has met or exceeded the standards established by GOTS-ECOCERT and OEKO-TEX ECO PASSPORT. For further details on these standards please visit www.ecocert.com and www.oeko-tex.com/ecopass.

- If hardware repair is required, Epson will generally perform this free onsite within greater metro locations (regional locations attract additional travelling charges). Cover can be extended up to a maximum total of 5 years through the purchase of optional CoverPlus. CoverPlus requires activation of an Epson Cloud Solution PORT account and connection of the printer. For further information, please see the specification tab.

- Platen grip pads can be applied to the small platen only to enable faster frameless loading and setting. The grip pads are user-replaceable to allow for issues related to wear, grime and ink bleed. They are not recommended for DTFilm production work.

Product Features

Quality Imaging

PrecisionCore Micro TFP printhead with VSDT and Precision Dot image processing for fine lines, superior half tones, solid and consistent colour ✓

Flexible output

Supports direct-to-garment (DTG) and direct-to-film (DTFilm) production ✓

Consistent quality with reduced maintenance

Uses UltraChrome DG2 ink for enhanced media support. Features ink-less nozzle status monitoring, auto-nozzle replacement, auto head cleaning, auto cap washing and white ink recirculation ✓

Output suited to all age groups

When affixed to clothing ink adheres to Oeko-Tex and GOTS-ECOCERT standards ✓

Simple to operate

Features fully automatic platen height adjustment, a touch panel control and is supplied complete with Garment Creator software ✓

Flexible installation

Compact and fully enclosed design suits a range of front and back-office applications including clothing design, customisation and event work ✓

Easy Integration

High speed Ethernet and Wi-Fi connectivity, also supports USB ✓

Product Contents

1 Epson SC-F1060 Direct to Garment/Film Printer

Product Design Process

Designed with uncompromised attention to detail that you would expect from Epson, this DTF printer is reliable and designed to maximise uptime and printing efficiency.

Direct to Garment or FIlm Process

The Epson Surecolor F1060 can print directly to garment or be used to create DTF prints for application to garments through heat press application.

Materials

New UltraChrome DF ink has was developed from product refined over multiple generations of Epson DTG printers. It works with films and powders available from a range of manufacturers. When applied to fabric and appropriately fixed it conforms to the latest Oeko-Tex® Eco Passport, GOTS and CPSIA standards..

Dimensions

Shipping Dimensions: L: 120 cm W: 87.1 cm H: 73 cm

Product Dimensions: L: 89.9 cm W: 69.9 cm H: 42.6 cm

Weight

Shipping Weight: 100 kg

Product Weight: 71 kg (no ink)

Ordering Process

Add to cart, proceed to checkout, once you fill in your details the site will display shipping options. Select how you would like delivered, proceed to payment. With 258 bit encryption, your information is kept safe. Choose from one of our payment options and complete your transaction with DTF Store.

Delivery

Currently waiting upon initial stock to arrive, please place your order as soon as possible and secure the initial stock allocation.

We will fulfil your order as soon as possible. Upon completion you will receive an email with tracking information, we have completed your order at our warehouse and your package is awaiting pick up from your selected freight method shipping agent.

We dispatch 90% of items same day if ordered before 2:00PM AEST. We are not Australia Post or a courier in any way. Once we have dispatched, please understand we can only see what you can see on your tracking. Allow enough time for it to arrive and enjoy your new items.

Anonymous (store manager) –

Great machine for low volume on demand printing